Mercedes-AMG PETRONAS F1 Team debuts bio-based carbon fibre composite material on rear wheel shields of W16 race car

- This weekend’s Azerbaijan Grand Prix saw the debut of pioneering bio-based carbon fibre composite material on our race car, marking the next step in our journey to use sustainable carbon fibre composites.

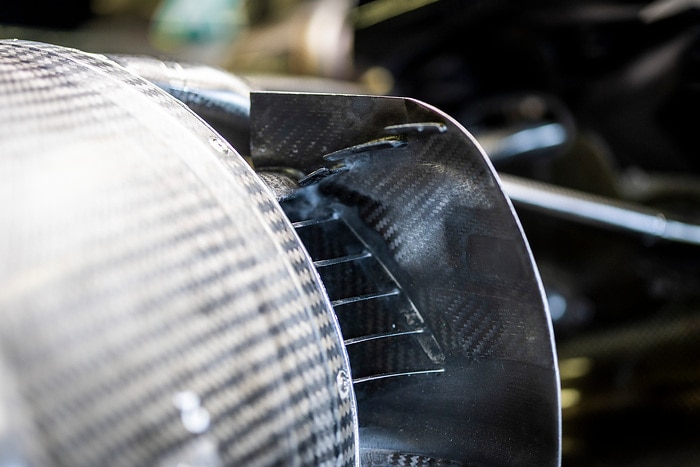

- The rear brake duct wheel shields on the W16 have been developed using a new resin that includes 30% bio-based materials.

- This marks the first time that the team has used sustainable carbon fibre composites on a technically performant component in race conditions.

- The groundbreaking development highlights how Formula One can lead the way in the application of sustainable materials without compromising on quality or performance.

The Mercedes-AMG PETRONAS F1 Team is pleased to announce the successful use of a bio-based resin on the rear brake duct wheel shields of the #63 W16 – which crossed the line in second place at the Baku City Circuit – following efforts to qualify and apply sustainable carbon fibre composites.

This groundbreaking development sees sustainable carbon fibre composites on a high-performance area of our race car for the first time, replacing 30% of the traditional resin material with those derived from renewable sources.

Applying these materials to the rear brake duct wheel shields, with their intricate aerodynamic surfaces, demonstrates the technology can withstand the extreme conditions of Formula One racing, and its potential for widespread adoption across the sport.

This innovative technology is a crucial step in our transition towards a more sustainable sport. It also marks the first time that the team has integrated sustainable carbon fibre composites on a technically performant component in race conditions.

Toto Wolff, Team Principal & CEO, Mercedes-AMG PETRONAS F1 Team

“In an era where innovation drives performance and shapes industry futures, the pursuit of smarter, faster, and more efficient technologies has become a defining challenge of our time. This project not only reflects our commitment to sustainability but also highlights the role of Formula One as a test bed for pioneering technologies that can benefit a range of industries. Our sport is the world’s fastest test lab, and these innovations represent our relentless pursuit of performance and appetite to contribute beyond the grid.”

Material innovation is a key step to meet our goal of achieving Net Zero across all scopes by 2040. The development of this bio-based material application has been made possible through close collaboration with Syensqo.

Alice Ashpitel, Head of Sustainability, Mercedes-AMG PETRONAS F1 Team

“We are proud to be powering sustainable innovation within Formula One, introducing sustainable carbon fibre composites on a technically performant component. This project with Syensqo highlights our commitment to reduce our environmental impact while maintaining the highest standards of performance. By integrating bio-based resin within a carbon fibre composite material, we are setting a new benchmark for the future of motorsport and beyond. The fact that these materials have been derived from by-products associated with the creation of bio-diesel is an added benefit and indicates the power of advanced sustainable fuels.”

Rodrigo Elizondo, President, Syensqo Composite Materials

“We are pleased to see our project with the Mercedes-AMG PETRONAS F1 Team come to life on the W16 race car. Our bio-based resin technology represents a significant step forward in sustainable materials innovation. By replacing traditional petroleum-based components with those derived from renewable sources, we are not only introducing circularity in our product design but also paving the way for future innovations. We are very pleased to see this material applied in such a high-performing environment, showcasing its potential for broader applications.”

Notes to Editors:

Carbon fibre composites are strong, lightweight materials formed of fibres and the resin that holds them together. By weight, approximately 60% of the composite material is formed of fibres, with 40% made up by the resin system. Impregnating the fibres with the resin system, followed by curing, creates a lightweight material with outstanding mechanical performance necessary to meet the unforgiving demands of Formula One.

This initiative further showcases the possibilities when it comes to sustainable high performance. We were the first global sports team to invest in and help scale the market for Sustainable Aviation Fuel and in 2024, we successfully powered our race and marketing trucks and generators across the European season using HVO100 biofuel.

Collaboration is vital to our success, with advancements in our materials sustainability strategy made possible by close co-operation with our carbon fibre and composites supply chain.

Syensqo

Syensqo is a science company developing groundbreaking solutions that enhance the way we live, work, travel and play. Inspired by the scientific councils initiated by Ernest Solvay in 1911, Syensqo brings great minds together to push the limits of science and innovation. As an established leader in composites for automotive applications, Syensqo has been developing novel and efficient solutions for motorsport OEMs for nearly four decades.

www.syensqo.com

Our latest Sustainability Report was published in July 2025. To view and for further information on our sustainability ambitions, please visit the Sustainability section of our website.